Production

This was not a small operation. The showroom in New York City boasted fourteen rooms. Two doormen opened the massive carved wooden doors for their exclusive clientele, and for extra special guests they rolled out a red carpet! Twelve attentive salesmen helped customers discuss possible commissions, browse the design binders, or look at presentation drawings.

Fulfilling orders took even more labor. First, the team of twenty draftsmen worked up designs and presented them to the architect and client. Estimators worked out the cost. Once approved, the item went into production and after completion, they took a picture before shipment.

Step into the shoes of the hundreds of people who designed, made, and sold the objects around you.

DESIGN PHOTO BOOKS

These pages, from a photo binder, represent a collection of over 50,000 images. Once complete an item was photographed, and its assigned design number written in the bottom margin (i.e., C15438). Binders were mostly arranged by types such as floor lamps or chandeliers and stored in specially made mahogany cabinets. Prospective clients could look at these binders in order to choose a design.

DESIGN PHOTO BOOK

EDWARD F. CALDWELL & CO.

NEW YORK CITY, NEW YORK, 1902-1911

CARDBOARD AND PAPER

LOAN COURTESY OF SMITHSONIAN LIBRARIES, COOPER HEWITT, SMITHSONIAN DESIGN MUSEUM

DESIGN PHOTO BOOK

EDWARD F. CALDWELL & CO.

NEW YORK CITY, NEW YORK, 1902-1911

CARDBOARD AND PAPER

LOAN COURTESY OF SMITHSONIAN LIBRARIES, COOPER HEWITT, SMITHSONIAN DESIGN MUSEUM

ARRETINE WARE

Beginning around 1903, Caldwell began making copies of ancient Roman ceramics from Arezzo, Italy. Arretine ceramics are characterized by delicate scenes cast into the sides. Caldwell took impressions of the originals at the Museum of Fine Arts, Boston from gutta percha and recreated them using the Galvano process.

COVERED BOWL

EDWARD F. CALDWELL & CO.

NEW YORK CITY, NEW YORK, 1906-1910

PATINATED & GILDED COPPER

LOAN COURTESY OF THE CALDWELL FAMILY

Since their introduction in the early 1900s, Arretinestyle bowls remained popular gifts well into the 1920s. Each baseball season, New York Yankees owner Jacob Ruppert (1867-1939), visited the Caldwell showrooms and purchased fifty decorative items, like this bowl, to present to the team’s players. Updated with ball feet, Arretine bowls were used as candy dishes in the Jazz Age.

BOWL

EDWARD F. CALDWELL & CO

NEW YORK CITY, NEW YORK, 1910-1925

SILVER PLATE OVER COPPER & BRASS

LOAN COURTESY OF SUSAN CONWAY

The liner of this bowl has been removed so that the bead surface of the Galvano process can be observed.

BOWL

EDWARD F. CALDWELL & CO.

NEW YORK CITY, NEW YORK, 1919

SILVER PLATED COPPER

LOAN COURTESY OF THE CALDWELL FAMILY

Upon his leaving the Fine Arts Commission to become assistant director of the U.S. National Park Service, Arno B. Cammerer (1883-1941) received this Arretine bow from his colleagues on the commission.

PLATE

EDWARD F. CALDWELL & CO.

NEW YORK CITY, NEW YORK, 1920s

SILVER

LOAN COURTESY OF A PRIVATE COLLECTION

This ancient Roman-style classical plate is displayed here upside down so that evidence of the Galvano process can be seen. Notice the small spherical beads all over the surface, which form when the silver migrated to the pattern while in the Galvano tank.

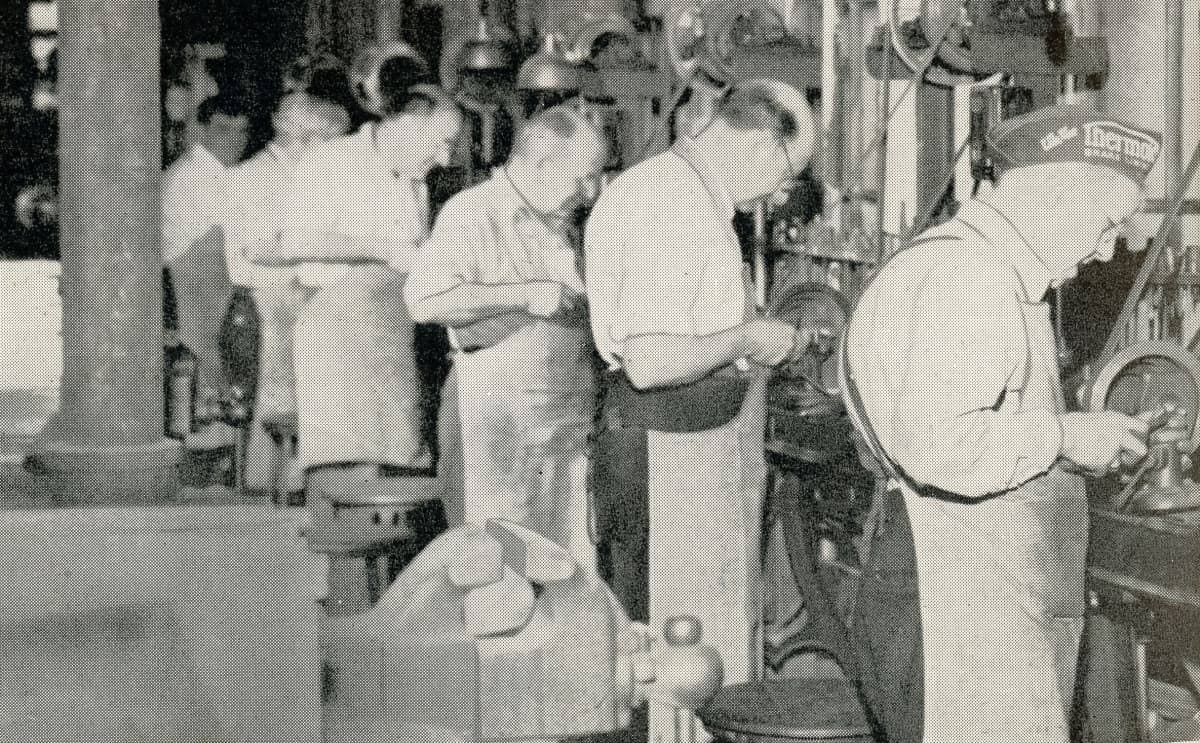

CHAMPLEVÉ

The practice of champlevé can be traced back to ancient Egypt but especially flourished in France, Belgium and Germany during the 11th and 12th centuries. Champlevé is made by carving out channels into metal and then filling the voids with powdered vitreous enamel. The enamel is melted and fused into place and once cooled, the surface is polished smooth. Caldwell began making champlevé in the 1910s. During the 1920s and 1930s, Clarence Barber and Albert Nesle visited museums in order to copy original examples. Caldwell created champlevé using the photo etching process. They modified Medieval reliquary boxes, tabernacles, and candle stands into humidors, letter holders, and electric lamps for modern clients.

HUMIDOR

EDWARD F. CALDWELL & CO.

NEW YORK CITY, NEW YORK, 1924-1925

GILDED BRONZE WITH CHAMPLEVÉ DECORATION, IVORY & COLORED GLASS

LOAN COURTESY OF THE FARRAND FAMILY

BOOKENDS

EDWARD F. CALDWELL & CO.

NEW YORK CITY, NEW YORK, 1914-1916

GILDED BRONZE WITH CHAMPLEVÉ DECORATION

LOAN COURTESY OF THE CALDWELL FAMILY

The design of these bookends derives from tabernacle cabinets.

CLOCK

EDWARD F. CALDWELL & CO.

NEW YORK CITY, NEW YORK, 1919-1920

GILDED BRONZE WITH CHAMPLEVÉ DECORATION

LOAN COURTESY OF SEIDENBURG ANTIQUES, NEW YORK CITY

BOX

EDWARD F. CALDWELL & CO.

NEW YORK CITY, NEW YORK, 1919-1920

GILDED BRONZE WITH CHAMPLEVÉ DECORATION

LOAN COURTESY OF THE CALDWELL FAMILY

BLOTTER COVER

EDWARD F. CALDWELL & CO

NEW YORK CITY, NEW YORK, 1919-1920

GILDED BRONZE WITH PORCELAIN ENAMEL DECORATION

LOAN COURTESY OF THE CALDWELL FAMILY

Champlevé, or enamelwork, one of Caldwell’s most popular lines, was made using the photo etching process. After creating the recesses, they were filled with colored porcelain enamel.

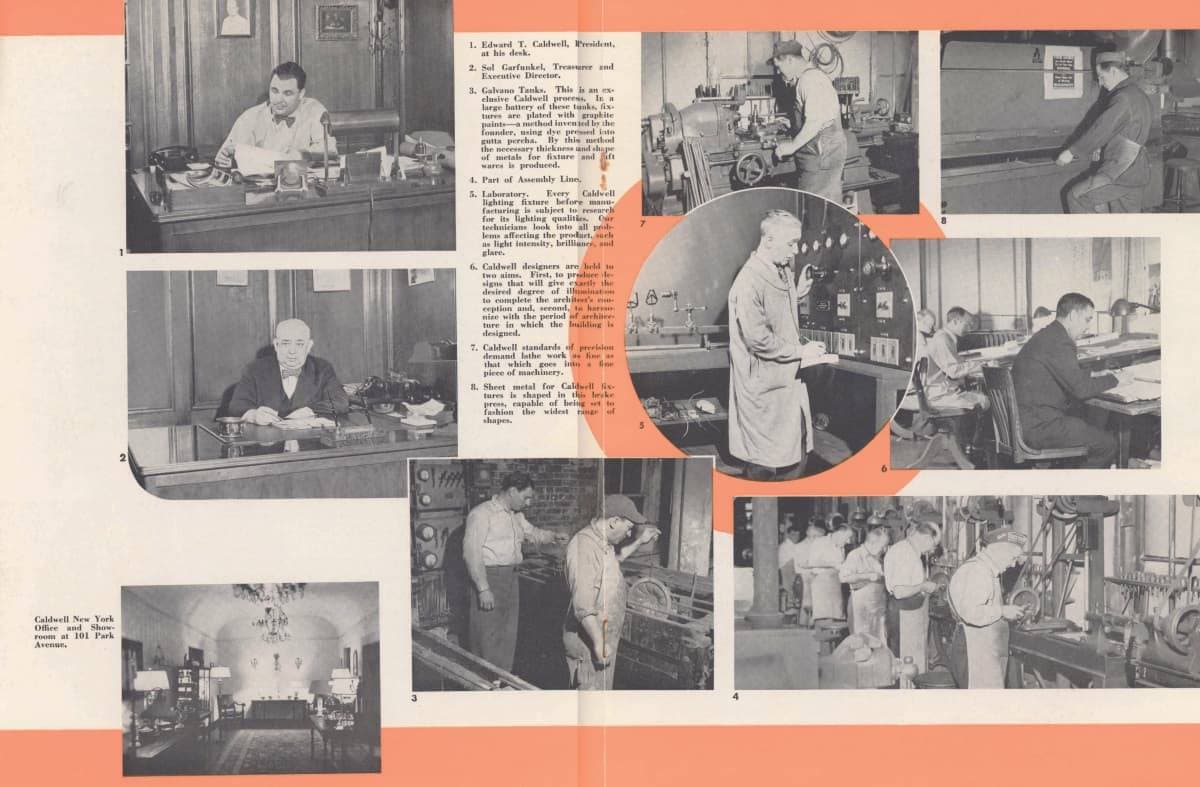

WORKFORCE

At its height, Edward F. Caldwell & Co. employed around 1000 people. The workforce composed largely of newly arrived immigrants from Europe including Italy, Germany, France, and Portugal. Though most who worked there remain anonymous, a few names have been identified through surviving company records and interviews of former employees. The list below has been compiled base on this information.

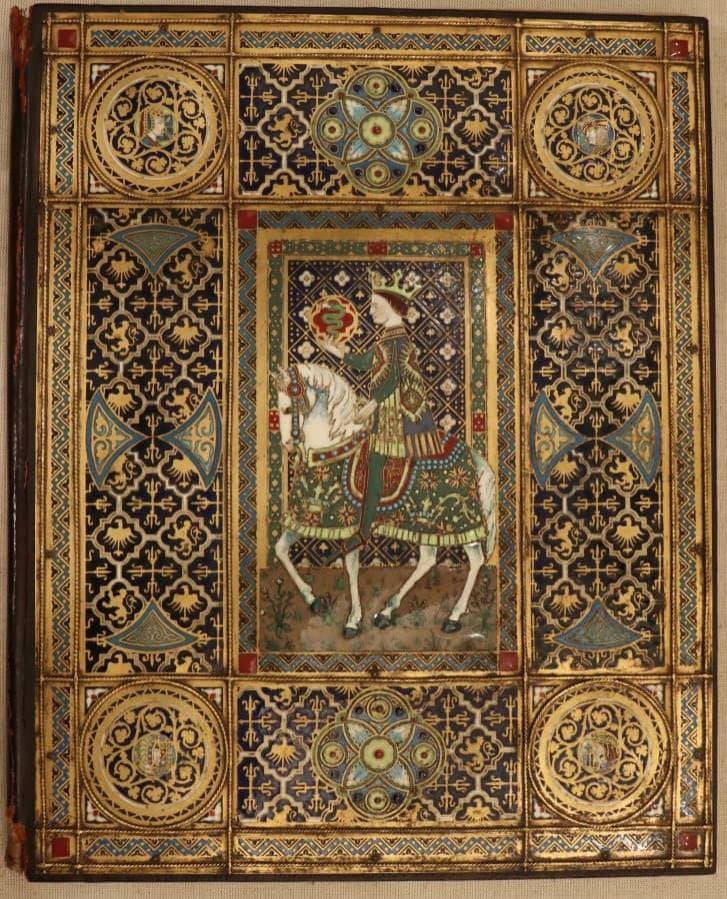

A MOST ILLUMINATING 50 YEARS: THE STORY OF EDWD. F. CALDWELL & CO., INC

EDWARD F. CALDWELL & CO., INC

NEW YORK CITY, NEW YORK, 1945

PRINTED PAPER

LOAN COURTESY OF THE CALDWELL FAMILY

This collage of pictures shows the production process at Caldwell. The men in picture 3 are making parts using the Galvano process, while machinists and metal shaping can be seen in photos 4, 7, and 8. The drafting crew is at work in photo 6 while lamp testing occurs in the lab shown in the center (5).

LOU GEHRIG

PHOTO COURTESY OF A PRIVATE COLLECTION

Before becoming a famous baseball player, Lou Gehrig had a summer job at the firm. He worked there in 1921 manning one of the metal lathes just before his freshman year at Columbia University.

PARTIAL LIST OF EMPLOYEES

Clarence Barber, DRAFTSMAN AND DESIGNER Edward F. Caldwell, PRESIDENT AND FOUNDER Edward T. Caldwell, TREASURER AND ACCOUNTANT J. Casino, DRAFTSMAN Oscar Hugh de Boyedon, SCULPTOR AND DESIGNER Mr. Elesse, DRAFTSMAN John Eto, DESIGNER Lou Gehrig, MACHINIST D. Guarino, DRAFTSMAN William Klehr, VICE PRESIDENT AND DESIGNER John Lanber, ARTIST, PRESENTATION DRAWINGS Mr. Linder, ARTIST, PRESENTATION DRAWINGS L. Livingston, SECRETARY Frank Moffett, DECORATOR AND ART DECO EXPERT Albert R. Nesle, SALESMAN/ESTIMATOR Mr. Ollman, DESIGNER Adelbert Potter, TOP SALESMAN Mr. Rexash, MODELER John Court Smith, WROUGHT IRON R. Vanti, DRAFTSMAN Victor von Lossberg, VICE PRESIDENT, PRESIDENT (AFTER 1914) AND CO-FOUNDER